compression force of gas springs|gas spring output force : company A gas spring can be given adjustable push-in force via a local knob or remote via a Bowden wire.Extended stroke is usually acquired through telescoping mechanisms, composed of one rod and . See more Resultado da Clínica de Massagem em Niterói: Especializadas em Massagem Relaxante e Sensual. Encontre Lindas Massagistas! AGENDE E RELAXE COM PRAZER!

{plog:ftitle_list}

WEBBolo Minecraft Quadrado. A versão quadrada é, decerto, a mais versátil, pois permite trabalhar melhor imagens, se for o caso. Portanto, se você mesma estiver pensando em fazer e decorar o seu e não possui .

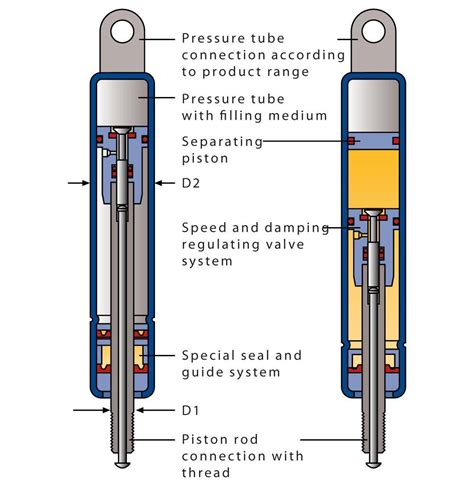

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on elastic deformation, uses compressed gas contained within an enclosed cylinder. They rely on a sliding piston to pneumatically store potential energy and withstand external force applied . See moreA gas spring consists of a sealed cylinder filled with a charge of high-pressure gas, a piston rod attached to a piston with a sliding seal, and some oil. The piston (or the cylinder wall) contains a number of channels that allow . See moreA gas spring can be given adjustable push-in force via a local knob or remote via a Bowden wire.Extended stroke is usually acquired through telescoping mechanisms, composed of one rod and . See morePoor ManufacturingGas springs are often used in office chairs, truck tailgates, and wheelchairs, just to name a few. A rare concern with gas springs is that if it is made cheaply, using oxygen as its internal gas, the oxygen will combust given . See more

• Shock absorber See more

Gas springs, also called gas dampers, tension springs, or gas-pressure springs depending on the setup and context, are compressed-air or oil cylinders that install in motion designs to damp forces and return kinematic .A gas spring can be defined as a hydro-pneumatic device, in which Nitrogen gas is contained with oil to provide the compressible and damping medium. Major parts of gas spring are piston, piston rod, pressure cylinder, and clamping .

- P1 Static – This is the nominal force of a gas spring. To measure this force, the spring is compressed 10mm then allowed to extend 5mm and held. This is the industry standard .Gas tension springs, also known as gas springs or gas struts, are mechanical devices commonly used in various applications to provide controlled and reliable force. These springs operate based on the principle of utilizing compressed .

pressure on gas springs

Gas spring forces are non-linear throughout the stroke and increase as the spring is compressed. This is often referred to as either the P2/P1 ratio, k factor or progression rate and can be controlled by either the .A gas spring functions as a hydro-pneumatic component that accumulates potential energy by compressing gas within a sealed cylinder, which is controlled by a moving piston. Unlike traditional springs, a gas spring does not depend .The spring characteristic curve describes the gas spring pro-gression force over the stroke, i.e. from the extended to the compressed state and vice versa. Unlike mechanical springs, gas .

The force ratio of a gas spring refers to the relationship between the extension force (when the gas spring is extended) and the compression force (when the gas spring is compressed). It is usually expressed as a percentage and can vary based on the design and specifications of the gas spring.

Discover the innovative features of Friction Locking Compression Gas Springs! These high-performance springs are designed with an internal pre-set friction control valve that expertly counterbalances the weight of any application. This .

Compression gas springs, also known as gas struts, are powerful and versatile components that harness the energy of compressed gas to provide smooth, reliable, and efficient force. They're often overlooked but play a crucial role in countless applications, from automotive lifts to furniture mechanisms. Their ability to provide controlled movement and support makes them .Gemini Gas Springs™ can be built to client requirements with respect to speed, damping length and progression rate. Extension speed depends on orifice diameter of the piston, damping length can be set to client requirements. Progression is the linear increase of force when compressing a gas compression spring and depends on cylinder volume.In this context, F denotes the gas spring force, k represents the spring constant in N/mm (force change per unit of compression), and X indicates the deflection distance in mm. Damping Control In addition to lubricating the piston, seals, and piston rod, the oil within a gas spring also plays a crucial role in controlling the spring's velocity .The Ultimate Guide to gas tension springs: What You Need to Know Gas Tension Springs: An Introduction Gas tension springs, also known as gas springs or gas struts, are mechanical devices commonly used in various applications to provide controlled and reliable force. These springs operate based on the principle of utilizing compressed gas to generate the necessary .

Our renowned fixed force "Swift and Sure" compression gas spring range is an incredibly adaptable product offers a reliable solution for a wide range of engineering needs. This gas strut is available in both carbon and stainless steel, in an extensive range of sizes, and end fittings for a wide variety of applications.Choose from our selection of gas springs, including over 2,800 products in a wide range of styles and sizes. In stock and ready to ship. . Compression Force. Less than 100 lbf. 100 lbf to 199.9 lbf. 200 lbf to 249.9 lbf. 250 lbf to 499.9 lbf. 500 lbf or greater. . Corrosion-Resistant Reducible-Force Gas Springs with Eyelet Fittings.The force in a compression gas spring increases the more it is compressed, in other words as the piston rod is pushed into the cylinder. This is because the gas in the cylinder is compressed more and more due to displacement changes inside the cylinder, thereby increasing the pressure that results in the axial force that pushes the piston rod .Fixed Force Compression Gas Springs – Swift and Sure – A self contained standard gas spring solution for lifting, supporting, counterbalancing and tensioning. Friction Locking Compression Gas Springs (External & Internal) – Stop and Stay – A gas spring that lifts and stays in any position.

JP is one of the most skillful compression gas spring manufacturers in China. W e offer compression gas springs of a wide range of forces and dimensions for you.. We ha ve been designing and manufacturing gas springs since 2003, serving 100+ clients from various industries, including automotive, medical, furniture, machinery, railway, and more.Our gas springs are designed for ambient temperatures of between -30 and +80°C. If possible, avoid intensive use at the extremes of this temperature range. Reducing/increasing ambient temperature also means a reduction/increase in gas spring force. 5. Gas springs are designed to handle axial loads. Avoid radial forces (lateral forces).The spring characteristic curve describes the gas spring pro-gression force over the stroke, i.e. from the extended to the compressed state and vice versa. Unlike mechanical springs, . The difference between the force lines for the compression and ex-tension direction, F R, is the result of friction effects. Gas spring forces are non-linear throughout the stroke and increase as the spring is compressed. This is often referred to as either the P2/P1 ratio, k factor or progression rate and can be controlled by either the dimensions of the gas spring or its oil level. . To give you a guide as to the tolerance for our standard compression gas springs .

Hooke's law: the force is proportional to the extension Bourdon tubes are based on Hooke's law. The force created by gas pressure inside the coiled metal tube above unwinds it by an amount proportional to the pressure. The balance .

In a compression gas spring the shock absorption or dampening occurs in the compression . A reducible gas spring has an adjustment style for gas shocks in which gas is let out to permanently reduce force capacity. In a locking gas spring the position can be locked at ends or in the middle of stroke. Valves can be included for fluid .

F0 (Start-up force): When the gas spring remains in an extended status for a while, the initial force that presses the piston rod.; F1 (Minimum extension force, this force is what we want to calculate.): During the .Explore the gas spring force diagram on our page. Understand the mechanics and applications of gas springs with detailed insights. Call us if you needs assistance. . F3=Compression Force Piston Rod Extended F4=Compression Force Piston Rod Retracted FR(Friction force)=F3-F1, F4-F2. Need more details? Contact us.This can be varied from 1.1 to 1.6 in a given spring, depending on application requirements. Standard gas springs have Force Ratios typically ranging from 1.2 to 1.4. . Most gas springs dampen during extension for controlled opening motion, but they bypass dampening during compression for easier closing. Compression dampening is optional.

Adjustable gas springs allow you to customise the amount of force or pressure within the gas spring. This flexibility makes them ideal for situations where you may need to fine-tune the lifting or supporting force. Compression Gas Springs: Compression gas springs are typically used in applications where the primary function is to compress or push.How does Gas Spring work? While applying force to the piston rod, did you think that How gas spring works? What is the principle of Gas Spring? According to Boyl’s law, the volume of internal gas decreases resulting in a proportional increase in pressure. The inner gas is compressed by applying force on the piston, gas stores energy, and oil .

Standard compression gas springs (also known as gas struts) are self-contained force storage devices used in a wide range of industries to provide a compact, high force solution to aid the lifting, counterbalancing and damping of applications. . All gas springs can be charged at the force you specify. If you are not sure of the force required .Compression gas springs, often referred to as gas struts or gas springs, are ingenious devices that harness the power of compressed gas to deliver smooth and controlled motion. These compact and versatile components are ubiquitous in a wide range of applications, from automotive liftgates and furniture to medical equipment and industrial machinery. Compression gas springs work much like traditional . As the downward force exerted on a compression spring increases, the coiled wire stores progressively more and more energy. It will only release that energy, as either a sudden or a gradual ‘push back’ movement, once the force holding it down is removed or sufficiently reduced. .- P1 Static – This is the nominal force of a gas spring. To measure this force, the spring is compressed 10mm then allowed to extend 5mm and held. This is the industry standard position for a gas spring force output. - The difference between P3 and P1 values is the dynamic friction. The same is true for the difference between P4 and P2.

Compression gas springs, often referred to as gas struts or gas lift supports, have emerged as a game-changer in countless industries, offering a compelling blend of strength, control, and precision. These ingenious devices leverage the power of compressed gas to provide smooth, controlled motion and support, revolutionizing the way we design .Compression gas springs, also known as gas struts or gas shocks, are essential components for various applications, offering a reliable and efficient solution for controlled motion. These springs utilize compressed gas, usually nitrogen, to provide a consistent force for lifting, lowering, or dampening movement. With their inherent advantages, such as smooth operation, .

Fixed Online Gas Detector

Combined OTR/WVTR Analyzer

webDeadloch TV-MA 2023 - Present 1 Seasons Crime Comedy List 100% 21 Reviews Avg. Tomatometer 88% 500+ Ratings Avg. Audience Score A man turns up dead during the Tasmanian Winter Festival.

compression force of gas springs|gas spring output force